Prototype Case Study

WHEN A FUEL TANK IS NOT JUST A FUEL TANK

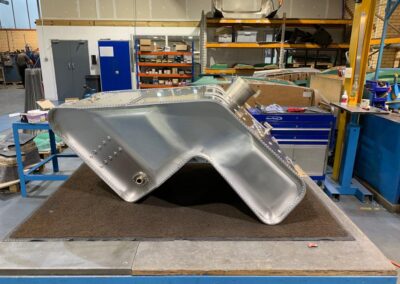

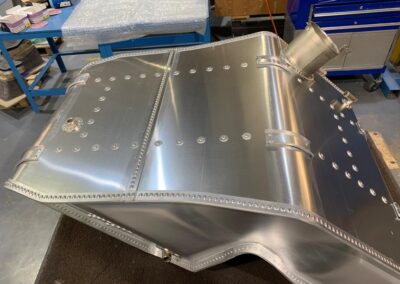

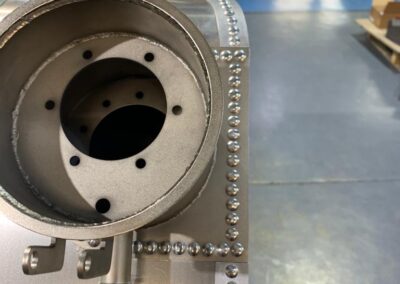

The fuel tank was required for a revival vehicle. It was a visible assembly in the car, so needed to have the best aesthetic surface finish possible and that all manufacturing processes had to be considered to limit and deformation.

Aluminium fuel tank tools, fixtures, and processes capable of producing two fuel tanks per year were required.

It was clear that based on the volume required that the tooling and panel manufacture would be at a prototype level. Therefore, simple CNC cut formers in resin tool board were produced. The formers were then used to hand form the panel shape by our skilled sheet metal artisans. This included rolling, wheeling, assembly and polishing.

The timing to complete the panel was five weeks from start to finish.

All parts prior to assembly were quality checked for aesthetic and dimensional excellence. Once fully constructed a final Quality check was carried out.

The fuel tank was fitted to the vehicle and was perfect fit.

Creating quality

Crafting perfection

GET IN TOUCH

aspects of our business as far as we’re able!